Matrimatic - The history of sewing machines

Matri Sewing machines since 1929

Matri sewing machines since 1929

Through all the experiences that Matri, founded in 1929, now has with all kinds of sewing

machines, overlockers and embroidery machines, it is a logical step to bring a versatile

sewing machine on the market.

Under the brand name Matrimatic thoughtful, sharply priced sewing machines are developed

with which many hobby sewers can get along.

Whether for the beginner or the more experienced seamstress that has higher demands on what a machine

should be able to do, the Matrimatic with its affordable price will be a machine for many.

One of the most famous model of Matrimatic sewing machines is the jubilee 4:

strong, easy and affordable.

Of course, the sewing machines from our own brand that we carry are of the very best quality.

The Matrimatic is characterized by the huge ease of use, for example, a free arm

and auto threader, and large number of stitches and the great price / performance ratio.

The history of Sewing Machines :

Around 1700 the Renaissance period. Clothing with lots of bells and whistles. At that time,yet everything was made by hand. If there was a need for something, it would have been the sewing machine.

Around 1700 the Renaissance period. Clothing with lots of bells and whistles. At that time,yet everything was made by hand. If there was a need for something, it would have been the sewing machine.

The German Weisenthal, who in 1755 lived in England, invented a needle that had a sharp point at both sides and an eye in the middle. Others, like Madersperger and Greenhough, used this needle also. They are still found today in the embroidery industry.

In 1790, the English cabinetmaker Thomas Saint applies for a patent for a wooden sewing machine with which a chain stitch could be made. Saint Thomas is considered the inventor of the sewing machine. His chain-stitch machine was designed for use in workshops for making shoes and boots, the heavier work so to speak

In 1800 Balthazar Krems from Mayen in Germany, manufacturer of nightcaps invented the stretch chain stitch. He first used a needle with the eye at the point. He obtained, as a result a loop on the underside of the fabric.

In 1814 The Master Tailor Joseph Madersperger from Kufstein, Austria, constructs a two needle sewing machine to sew blankets. Since his resources failed, he could not get this machine into production. He died in 1850 at age 82, in Vienna in a retirement home for the needy.

The Frenchman Barthelemy Thimonnier from Arbeste, the French Rhone department, received a patent in 1830 on his chain stitch machine. But an ignorant and angry mob of tailors, who saw in his machine a threat to their profession, destroyed most of his machines. Thimonnier fled and never recovered from that fateful battle. As a poor show-director, he demonstrated later on his machine in the circus, as a mechanical curiosity. He was overjoyed while doing these demonstrations. He died in 1857 completely penniless. This Thimonnier machine had to sew every stitch by the push of the pedal. The loops of the chain stitch layers on top of the fabric. The seamstress had the responsibility to ensure that the fabric, after each stitch, was pushed further sidewise to obtain the same stitch length wise.

In 1834 Walter Hunt, a typical self-made man (his designs include the first safety pin and the first fountain pen), between 1832 and 1839 was particularly interested by the sewing machine. He succeeded, by means of a shuttle for the first time to form a lock stitch as we know it today. He is the founder of the sewing principle, where 2 threads are used, a lower and an upper thread.

In 1845, The American Elias Howe, from Spencer (Massachussetts) also built one of the first machines in which the second thread is used in a shuttle. It is very likely that the shuttle of the weaving looms has inspired the American mechanics. Howe's success depended for years on this invention. When he, in 1845, with his friend and financier Fisher, sewed a garment with his newly long shuttle machine first with a double stitch, he believed to have reached his goal. Meanwhile, other Americans had been busy perfecting the sewing machine. His main rival, Isaac Merrit Singer, constructed a similar machine, and of course it came to a process

for right of priority. After long litigation Howe won the process. It is calculated that Howe received, in the form of royalties on machines made up to the period of the expiry of his extended patent -- September 1867 -- which was also the month of his death, a sum of not less than two millions of dollars. With his own resources he equipped, during the American Civil War, a whole military brigade. He died at the age of 48 in 1867

In 1850 A license is granted to Wheeler & Wilson, of Bridgeport (Connecticut) in the United States. Allen B. Wilson built the first sewing machine with rotating hook, which is known generally as the Wheeler & Wilson principle. The rotary hook, is bevelled and notched so that it opens and expands the upper thread loop, causing it quite to enclose the bobbin of under thread, after which it throws it off and the so-formed lock stitch is pulled up and tightened either by an independent take-up motion as in recent machines, or by the expansion of the next loop as in the older forms. The bobbin , lenticular in form, and its case, fit easily

into a circular depression xithin the hook, against which they are held by the bobbin holder. The Wheeler & Wilson Sewing Machine Company was very leading in the area, but was not financially strong enough to exploit the rapid evolution. She was bought by the Singer Company. Isaac Merrit Singer, a former circus director has the great merit of making the sewing machine available to the general public. He is the great developper of the American sewing machine industry.

The first machine made by Isaac Merrit Singer was patented in 1851. This sewing machine was packed in a wooden box which when opened could be used as a threadle machine. Singer did not realize that he could patented this invention. When pointed out to him it was too late, the threadle was already in public use. This machine was very heavy and more suitable for industrial than household use.

1851-1860 Creation of a new generation of machines.The German names like Koch, Gritzner, Pfaff, Kayser, Muller, Mundlos, Durkopp, Biesolt, Locke, Nothmann, Bear and Rempel, were then known to the world. Only Pfaff is left. The base of the Pfaff Industrie was laid by Georg Michael Pfaff.

A small chain stitch machine 1855 of the Company Seeling from Paris. Elagant but no closed form. The spool is located on the needle bar.

The story of the invention of this popular type of chain stitch machine is remarkable. In 1855 James Gibbs, a farmer from Virginia (America), saw a wooden Grover and Baker machine in a newspaper ad and was surprised on how the machine could sew. The mechanism at the bottom of the machine was not visible, so it wasn't clear to Gibbs that there was a bobbin thread. He conceived the idea of a rotary hook, but did not develop this principle further. Gibbs produced later with Charles Willcox a sewing machine in which the principle of the previously developed rotary hook was used, which he patented in 1857. The company still exists but only makes industrial machinery.

In 1855 Wheeler & Wilson show their machines with transport of fabric for the Universal Exhibition of Paris.

1858 In America, more than 100,000 sewing machines already in are in use and enterprising engineers start being interested in sewing machine and later manufacture. The machine shown is a chain stitch.

1860 This elegant machine is constructed in France and has a free arm.

An improved model of Howe in 1860. Features: a perpendicular needle insertion, a straight needle, a big long bobbin and a flywheel at the bottom.

The original Singer machine was heavy and uncomfortable fo home use, but in 1858 Singer brought a lightweight Singer Family Machine on the market, and in 1865 the additional New Family Machine. This machine was in production for about 20 years and more than 4 million machines were produced. Generally, this machine was similar to the machines that were producted in the early 20th century.

1867 A small machine that is strikingly similar to a children's machine it seems. This machine was produced by the firm of Wanzer & Co. from Hammilton from Canada and has a winding spool.

1870 More and more machines are produced with a bobbin, this machine was manufactured in Rouen.

1870 This machine works with a chain stitch, the speed is getting more and more important this machine makes 200 stitches per minute.

1878 The small "Legat" from Paris. A model with a oscilating shuttle, which by pressing the button is being started. Horizontal oscilating shuttle.

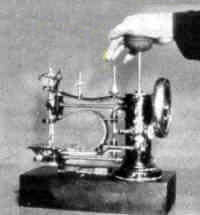

In 1879 William Jones from Guide Bridge, Lancashire took their first sewing machine patent in 1869 and founded a company which is still manufactures sewing machines. This type of hand machine was in production from 1879 to 1909. This machine was manufactured for export to tropical countries. The non-painted parts were chrome plated to prevent rusting and came with a steel case.

1880 The 'Original Rhemania' of the Firm Junker & Ruh. A real German construction: Solid and heavy construction. Long shuttle. The upper back can be overturned. Drive is done by means of the large hand wheel.

1882 The year of the zig-zagmachine.

The first zig-usable zagmachine sees the world. The German, John Kayser, from Kaiserslautern, takes them to the market. Kaysers construction made it possible to set the zigzag stitch larger or smaller by the use of the zigzagbutton. This machine has already an elongated hole of the needle plate, as this is the case today with the modern zig-zag machines.

This sewing machine was manufactured in 1888 and is the last model made by the Howe Machine Company, which after the death of Elias Howe in 1867 was conducted by his sons. Although Howe had a patent on its method of manufacture of sewing machines since 1850, he produced himself not befor 1865. Meanwhile his brother Amasa produced from 1854 sewing machines under the name of the Home Sewing Machine Company, whichlasted until 1873 1900-1940 A period without any significant developments. Besides the sewing machine with the shuttle, the machine with the bobbin becomes very popular. The models in this period hardly changed and all the machines were and remained black in color with gold and silver ornaments and often inlaid with mother of pearl.

However, new is, the introduction of the Pfaff 130 zigzag sewing machine with rotary hook, designed by a Dutch engineer. Particularly suitable for tailors and home producers. Until approximately 1950, hundreds of thousands of this type of machines is produced. Today, this machine is still very popular in countries like Pakistan and India, where it is used for the home industry.

1940 The sewing machines which until 1940 were on the market were made of cast iron, were so heavy in weight, had a black color, were called flat design and were operated by hand or threadle. In 1940, a turnaround in the sewing machine industry. The Elna-I comes on the market. As the inventor-constructor, (ir Ramond Casas, originating Spaniard which later emigrated to Switzerland) until that moment had never been engaged in sewing machines, and was not influenced by certain design principeles, produced a totally different kind of sewing machine: the machine was made of light metal and was therefore truly portable because the machine housing was manufactured from light metal, the whole mechanism had to be modified accordingly, so the machine would be in complete balance while in use

In contrast to the hitherto conventional black color, this machine has been released in a modern green color in the construction, the inventor also sought simplicity in operation. The machine was equipped with a built-in motor the machine was equipped with built-in sewing light The machine was fitted with a free arm (up to then only known by the sewing machines industry) the machine was packed in a metal case, which also could serve as an extension table

All this brought lots of change in the household sewing machine industrie. Due to the success Elna had other brands worldwide were other brands machines more or less forced to follow Elnas path. In 1952 Elna caused another evolution, by the release of the Elna Super Matic. This machine, which works by means of loose interchangeable cams, it was possible to change the sequence of the left-right movement of the needle. This made it possible to manufacture decorative stitching, based on zigzag but also practical stitching as the serpentine line, the blind hem, etc.

But not only this! Because it was also possible with the "double" cams, to regulate forward and backward transporting of the fabric, thus it was possible to obtain any desired pattern. But mostly practical stitching with backwards moving. Like the household overlock the stretch triple reinforced seams etc.